In any industry, operational failures can have severe consequences, leading to disruptions, financial losses and even catastrophic incidents. These failures occur when systems, processes or human actions deviate from established standards or best practices, resulting in unintended outcomes. Understanding operational failure is crucial for organisations to mitigate risk, enhance safety and maintain operational excellence.

What is Operational Failure

Operational Failure is any event or circumstance that disrupts the normal functioning of an organisation’s operations. It can manifest in various forms, such as equipment malfunctions, procedural errors, communication breakdowns or inadequate risk management. Essentially, operational failures arise when one or more components of an organisation’s operational ecosystem fail to perform as intended.

Incident investigation plays a crucial role in learning from and preventing operational failures, including those that encompass HSEQ incidents. Thorough and systematic investigation of incidents is essential for identifying root causes, understanding the sequence of events and uncovering underlying systemic issues that contributed to the failure. By conducting comprehensive incident investigations, organisations can gain valuable insights into the weaknesses or vulnerabilities within their processes, procedures, equipment or human performance factors. This knowledge enables them to implement targeted corrective and preventive measures, addressing the identified gaps and deficiencies.

Effective incident investigation, such as the Kelvin TOP-SET Methodology, promotes a culture of continuous improvement, as lessons learned from past failures can be translated into enhanced safety measures, optimised operational practices, and strengthened environmental and quality controls. Ultimately, a robust incident investigation process empowers organisations to break the cycle of recurring failures, mitigate risks proactively, and cultivate a resilient and sustainable operational environment that prioritises the wellbeing of employees, the community and the environment, while maintaining high quality standards.

Examples of Operational Failures in Industry

In TOP-SET’s 35+ years of experience, the industries below are particularly vulnerable to operational failures due to the complexity of their operations and the critical nature of their services. Of course, operational failure occurs in all industries, however these are some examples of incidents where TOP-SET has been used to manage incident investigations.

Rail:

- Signal Failures

- Track Maintenance Issues

- Human Error

Logistics:

- Inventory Management Errors

- Transportation Delays

- Warehouse Mishaps

Ports and Shipping:

- Crane and Equipment Failures

- Vessel Collisions or Groundings

- Cargo Handling Errors

Energy:

- Power Plant Outages

- Pipeline Leaks or Ruptures

- Renewable Energy System Failures

What is the impact of Operational Failure?

The impact of these operational failures can have far-reaching consequences, including:

- Financial Losses: Disruptions, delays and accidents can incur substantial costs, including lost revenue, fines and compensation claims.

- Reputational Damage: High-profile incidents or recurring operational failures can tarnish an organisation’s reputation, eroding customer trust and market position.

- Regulatory Consequences: Failure to comply with industry regulations or safety standards can result in penalties, licence revocations or increased scrutiny from regulatory bodies.

- Environmental Impact: Certain operational failures, such as hazardous material spills or emissions, can have detrimental effects on the environment and lead to costly cleanup efforts.

- Employee Safety: Operational failures can compromise the safety of employees, potentially leading to injuries, lost productivity and legal liabilities.

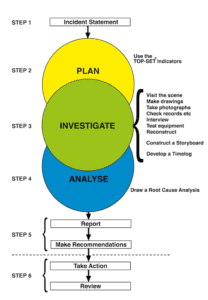

To investigate and effectively address operational failures and reduce the risk of future incidents, organisations must have a robust investigation process in place. The Kelvin TOP-SET Incident Investigation System is comprehensive and designed to identify root causes, implement corrective actions and continuously improve operations. It is easy-to-use, logical and highly practical. More than just root cause analysis, TOP-SET is a complete incident investigation system covering:

- The Incident Statement

- Planning (using the TOP-SET Indicators)

- Investigating

- Analysis

- Reporting and making SMART Recommendations

- Taking Action & Reviewing

Using the TOP-SET Indicators when planning what to investigate encourages wholly divergent thinking. This ensures accurate and high-quality data input for analysis, i.e. no stone is left unturned, and helps minimise cognitive bias.

By recognising the potential for operational failures, and adopting the Kelvin TOP-SET Incident Investigation System, organisations can effectively identify and understand their causes to implement targeted SMART corrective actions and prevent similar incidents from recurring. This proactive approach to incident investigation mitigates risk and promotes a culture of continuous improvement, enhancing safety, operational efficiency and organisational resilience. This is vital for ensuring the long-term success and sustainability of operations across all industries worldwide.